Bearings Make the World Go Round

Bearings are indispensably for smooth and effortless rolling, but many half-baked wisdoms are buzzing around.

Bearings played a pivotal role in the nascent industrial revolution, allowing the new industrial machinery to operate efficiently. The first patent for a radial style ball bearing was awarded to Jules Suriray, a Parisian bicycle mechanic, on August 3, 1869. This had also impact on the development of roller skates. James Plimpton’s first quad skates would not have been so successfully, without ball bearings.

Don’t Drop the Ball

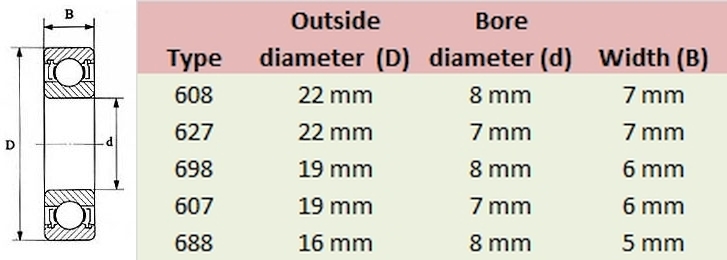

The basic form and concept of the ball bearing is simple. If loads are to be transmitted between surfaces in relative motion, the action can be facilitated in a most effective manner if rolling elements are interposed between the sliding members. The frictional resistance encountered in sliding is then largely replaced by the much smaller resistance associated with rolling. For roller skating two different sizes are commonly used, depending on the diameter of the axle. Trucks with 8 mm axles need bearings with 8 mm bore diameter, accordingly bearings with 7 mm bore diameter fit at trucks with 7 mm axles. 98% of the wheels you can buy for roller skating are designed for bearings with 22 mm outside diameter. From this it follows that type “608” or “627” are the sizes, you have to look for.

Some manufacturers are increasingly offering wheels, which have to be equipped with 16 mm diameter micro-bearings. Most advantage is the reduced weight. The difference of 4 grams compared to 12 grams results in a reduced weight of 64 grams per skate.

The ABEC Myth

When it comes to bearings, the term “ABEC” is heavily cited. ABEC is an acronym for Annual Bearing Engineers Committee. The ABEC committee established tolerances and specifications for the size and geometric accuracy of all bearings. The ABEC rating system uses odd numbers, ranging from 1 to 9. The higher the number, the tighter the tolerance of the bearing, and thus, the greater degree of precision. Bearing manufacturers from all over the world send their bearings to the U.S.-based ABEC committee to be rated. Sounds great. But a lot of misconceptions exist about the relevance of ABEC ratings to the performance of a bearing used for roller skating. Precision of the bearings is not such relevant for roller skating, because it is a non-precision application. Unless you are going 90 miles an hour.

For most industrial uses, the load put on a bearing is a radial load the forward and backward spinning motion. Radial loads are typical of a bearing that is only turning in one direction, as in an electric motor or a machine tool. For these functions, a high level of precision is required because the bearings turn at incredible speeds in one direction. Hence, ABEC measurements must be made to an extremely tight tolerance of a thousandth of an inch, or a hundredth of a millimeter. Significantly, the ABEC committee doesn’t test for axial or side loads. Although heavy or repeated axial loads shouldn’t be an real issue in roller skating, in skateboarding this could be a problem.

So: More important than ABEC ratings, skaters should look for the types and quality of materials that the bearings are made of. There are four different components to a bearing:

- The balls

- The inner and outer raceways

- The retainer or cage

- The seal or shield

For each of those components, a wide range of materials could be used.

Serve and Protect

Most of the skate bearing are closed at the sides. This keeps all of the internal parts (balls, cage) of your bearing protected from dust and dirt from the outside. There are two types:

- Sealed

- Shielded

The covering of sealed bearings is not removable and thus you are only able to get inside of the bearing for cleaning and lubricating purposes, if it is one-sided sealed. If both sides sealed, you can also lift one of seals with a sharp tool with destroying the metal seal, but without damaging the cage of the bearing. You probably guess, that this should be reserved for experienced DIY workers. To avoid misapprehension: “Sealed” isn’t impenetrable – water, dirt, and dust can get also slowly into sealed bearings.

Sealed is typical for industrial bearings. Because roller skating or skateboarding brings bearings in rather unusual dirty environments, manufacturers started to design bearings specifically for skating. These bearings are shielded, what means they are serviceable. They provide rubber “cap” which can be popped off to access the inner of the bearings and allow for easy cleaning and lubrication. In addition these bearings are also better prepared for axial or side loads. Nevertheless the recommendation “look for the types and quality of materials that the bearings are made of”, applies also for bearings designed specifically for skating. These bearings could be most appropriate, but excellent bearings for industrial use are superior to bad “skate bearings”.

Grease or Oil?

For a bearing to operate properly, it needs to be lubricated. The main focus for selection of a lubricate is the minimum running resistance – the minimum dynamic viscosity recommended for that use. Aspects like temperature resistance or lubrication at high rotational speed aren’t relevant for use in roller skates. The question “oil or grease” arises only in case of re-lubrication after you have cleaned the bearings. New bearings come with lubrication and can be used at once.

The lubricant used within the bearing will affect the speed, however less than often claimed. A common lubricant is grease. Grease offers protection against contaminants, but is not as fast as oil because it takes a slight amount of friction to melt grease to the proper lubrication consistency. Oil-lubed bearings require more maintenance because oil do not last as long in the bearing. It is worth noting that re-lubricating a bearing with a different type of lubricant isn’t bad, but matching them is preferable. My personal recommendation, the best of both worlds: SKF LGLT 2 fully synthetic oil based grease using lithium soap. It provides excellent durable lubrication performances at low temperatures with oil-like low friction torque.

The lubricant used within the bearing will affect the speed, however less than often claimed. A common lubricant is grease. Grease offers protection against contaminants, but is not as fast as oil because it takes a slight amount of friction to melt grease to the proper lubrication consistency. Oil-lubed bearings require more maintenance because oil do not last as long in the bearing. It is worth noting that re-lubricating a bearing with a different type of lubricant isn’t bad, but matching them is preferable. My personal recommendation, the best of both worlds: SKF LGLT 2 fully synthetic oil based grease using lithium soap. It provides excellent durable lubrication performances at low temperatures with oil-like low friction torque.

Let’s go Ceramics

While regular bearings are made from steel, ceramic bearings are made from ceramic silicon nitride (Si2N4). Ceramic bearing fans praise a reduced rolling resistance. Ceramic balls in bearings are rounder with a smoother surface and more uniform size. That reduces friction and can contribute to a less energy required to spin the wheels. A ceramic bearing is also harder than steel bearings, which improves durability. They also do not rust, and the hard ceramic balls grind the dust to smallest particles, so less maintenance should be required.

Most ceramic bearings for roller skating use are actually hybrid ceramic bearings, which combine a steel race with ceramic ball bearings. Full ceramic bearings use also ceramic races, but at ridiculously expensive costs. But the purchase of even hybrid ceramic bearings should be carefully considered as well. The small advantage has to be paid with 4-5 times the price of steel bearings. Even if you are now fancy ceramic bearings, consider the cited advice: “look for the types and quality of materials that the bearings are made of”. The differences in quality of ceramic skate bearings are widely.

6-7-8

Usually standard 608 or 627 skate bearings have 7 balls inside. Few manufacturers promote the advantages of bearings with only 6 slightly larger balls, or 8 slightly smaller balls. Both claim this should provide a “better roll”. Do you notice something? Unproven, contrary proposition.

Get your bearings

So when it comes to choosing bearings think simple. If you’re going to spend the money on a ceramic set of bearings keep in mind they can break easy and the benefit from it could be small. If you are staying with steel and looking for shielded skate bearings, adhere to reputable companies like Bones, KwiK, or Qube. Getting reasonably priced industrial bearings doesn’t always mean they’re the worst, if they are made by well-known industrial ball bearings manufacturers, like SKF, FAG, Timken, or NSK. In any case: Keep them clean and dry, and they should last you a long time.